Fully Automatic Can Filling Line

The complete aluminum can filling line is one of the most advanced and efficient equipment used in the beverage, mineral water, and other carbonated and non-carbonated drink industries. This production line, with high capacities of up to 90,000 cans per hour, is capable of meeting the production needs of large-scale companies. With these systems, the packaging process of beverage products is performed automatically, with the highest speed and precision.

Advantages of the Complete Aluminum Can Filling Line:

High Capacity: These lines, with production capacities of up to 90,000 cans per hour, are ideal for large factories and mass production.

High Accuracy and Quality: These machines fill cans with great precision, reducing waste and enhancing the final product quality.

Time and Cost Efficiency: The automated filling process reduces the need for manual labor and enhances production efficiency.

Variety in Beverage Types: The system can fill various beverages, including carbonated drinks, mineral water, energy drinks, and more, depending on market demand and consumer preferences.

High Energy Efficiency: These lines are designed to minimize energy consumption

We have illustrated an automated turnkey system for Can filling lines in the capacity from 10000 to 90000 cph. depalletizer, can filler and seamer, and palletizer are available individually, all other machines are part of the turnkey system.

If you click on the buttons, a short machine description is available.

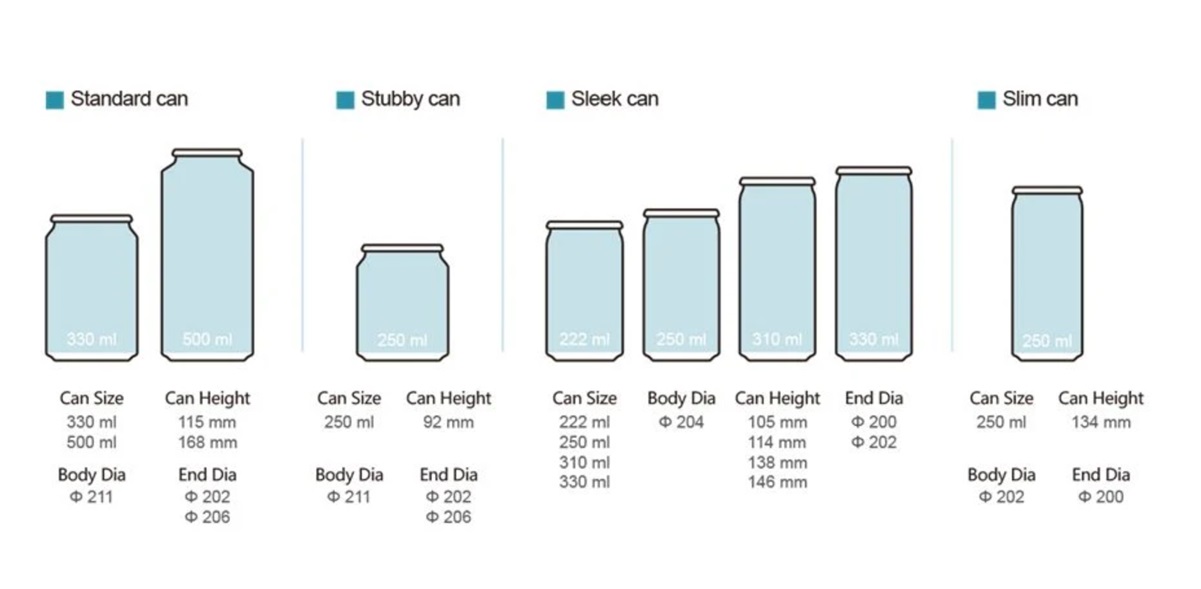

Types of aluminum can sizes:

-Standard can(330ml, 550ml)

-Stubby can(250ml)

-Sleek can(222ml, 250ml, 310ml, 330ml)

-Slim can(250ml)

-Can level fill Inspection

-Pasteurizer (for Beer product and Energy Drink)

-Cartoning Shrink

Can conveyor & Rinser ,& Pallet Conveyor

PDF Files coming soon.

Video

Heineken Can Filling and Packaging

Capacity: 42,000 cph

Complete Canning and Packaging line For Heineken Beer

watch the video >>

Video

Can Filling Machine

Capacity: 36,000 cph

Complete Canning line For Beer and Carbonated Drink

watch the video >>