YS-AS

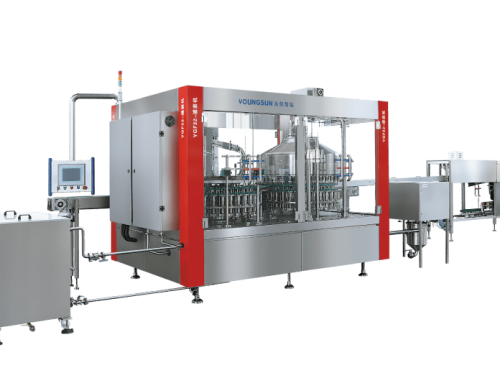

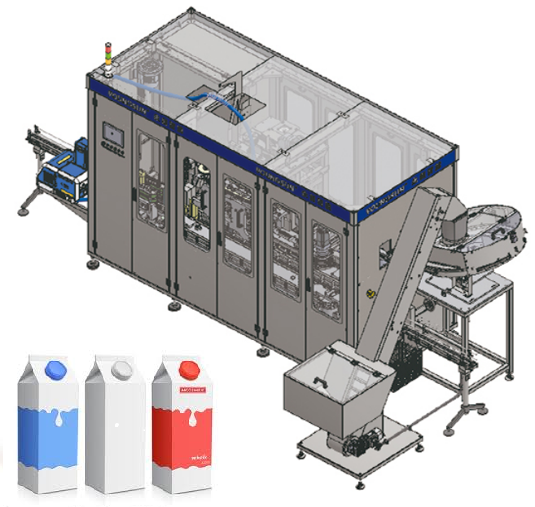

COMPACT FLEX Aseptic Carton Filling Machine

Capacity:

YS-AS /24,000 packs/hour for 200ml

YS-AFC/ 9,000 packs/hour for 100ml, 200ml, 250ml

YS-AF / 6,000 packs/hour for 1000ml

BRIEF INTRODUCTION:

Suitable for liquid and non-viscous products (pure milk, yogurt, juice, soy milk, tea drinks, etc.

Machine Features:

- The new type of tracked gripper ensures more stable production operation and higher production efficiency.

- Modular design, more efficient maintenance, function conversion, and performance improvement.

- Provide the safest sterile packaging, highest production yield, and lowest operating costs.

- Fully servo-driven, stable, and efficient, it is more convenient for personnel operation and cleaner production area environment.

- Intelligent HMI system, simplifying manual operation projects;

- Online monitoring of equipment operation status, prompt operation, and reduced dependence on operators throughout the production process.

* Add notice about your Privacy Policy here

Products that can be produced with the aseptic filling machine:

– Pure milk

– Juice

– Yogurt

– Tea drink

– Soy milk

– Plant protein beverages

-YS-SA1 SERIES STRAW APPLICATOR

-YS-CA1 SERIES CAP APPLICATOR

The Compact Flex Aseptic Carton Filling Machine is designed to meet the increasing demand for efficient and high-quality carton packaging in the food and beverage industry. This state-of-the-art filling machine combines advanced aseptic technology with a compact design, providing an ideal solution for small to medium production runs while maintaining top-tier hygiene standards.

-

Aseptic Technology

The machine is equipped with cutting-edge aseptic filling technology, ensuring that products such as juices, dairy, soups, and beverages are processed in a sterile environment. This guarantees the preservation of taste, nutritional value, and extends shelf life without the need for preservatives. -

Compact and Flexible Design

Its small footprint makes it an ideal choice for businesses with limited space, without compromising on performance. The Compact Flex offers exceptional flexibility, allowing for easy product changeovers and adaptability to various carton sizes and volumes. -

High-Speed Production

With a high-speed filling capability, the Compact Flex maximizes productivity. Its efficient filling process reduces downtime, increases throughput, and ensures consistent quality across every carton filled. -

User-Friendly Interface

The machine is equipped with an intuitive touchscreen control system, simplifying the operation and reducing training time for your staff. With real-time diagnostics and easy-to-understand instructions, operators can manage the entire filling process with ease. -

Minimal Product Waste

The precision filling system minimizes overfilling and underfilling, helping to optimize raw material use, reduce waste, and improve overall cost-efficiency. -

Eco-Friendly Design

Featuring an energy-efficient design, the Compact Flex machine uses minimal resources, promoting sustainability in your production process. Its recyclable materials and reduced carbon footprint make it an environmentally-conscious choice. -

Seamless Integration

The machine is easily integrated into existing production lines and can be customized to meet specific operational needs. Whether you’re looking to expand capacity or improve packaging quality, the Compact Flex delivers versatility and performance.