CGX —

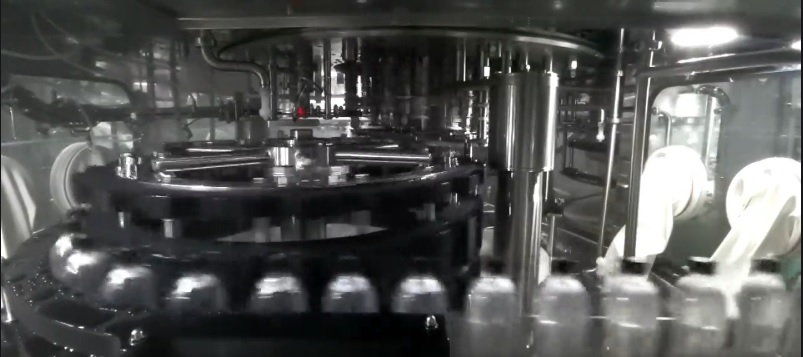

Combi-block

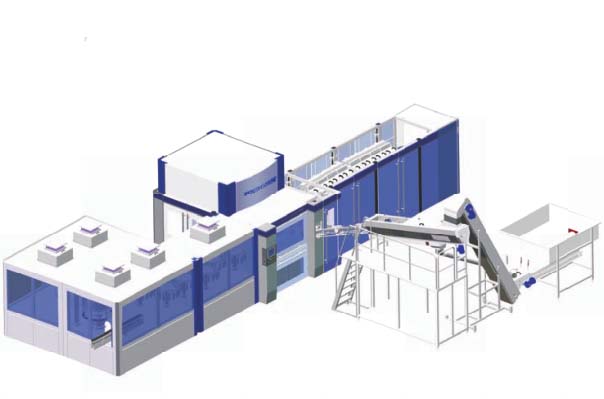

Blowing + Filling + Capping

(3 in 1 machine)

Capacity:

Up to 60,000 BPH

BRIEF INTRODUCTION:

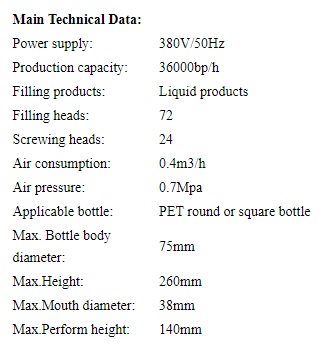

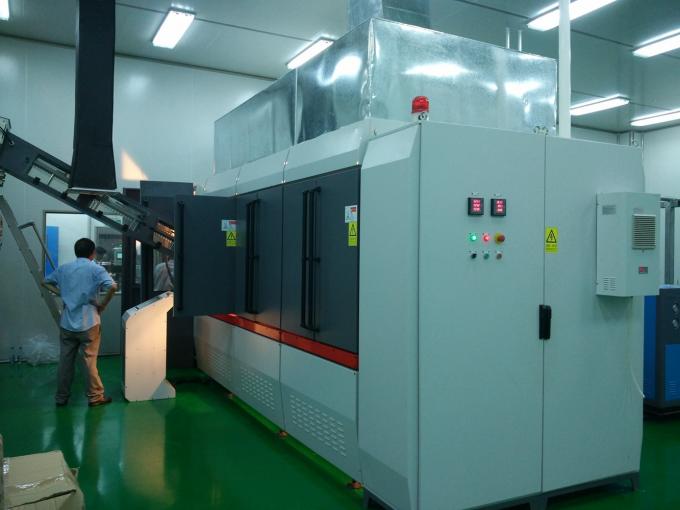

The blowing filling capping machine integrates the blowing system, filling system, and capping system. This reduces the transmission, empty bottle handling, and storage processes. It has a wide application in the beverage industry and the packaging of liquid products such as juice, milk, water, etc.

The capacity will be different depending on the characteristics of the products.

Machine Features:

1. Blowing, filling, and capping are integrated into one machine, Bottleneck handling in all processes.

2. Ion air-blowing dust-suction system and hydrogen peroxide sterilization are optional.

3. Siemens PLC control marks the machine as easy and stable.

4. The sanitary and washable capping system, intensive UV sterilization, and aseptic water rinsing sterilization for cap feeding are optional.

5. High efficiency, low energy, easy maintenance.

* Add notice about your Privacy Policy here

Products that can be produced with blowing filling capping machine:

– Water

– Milk

– PET bottles

– Fruit juice and tea

– Carbonated drinks

– Aseptic

– Hot materials

Rotary blowing systems that can produce up to 60,000 bottles/h of small and medium format

3 in1 Combi block machine is the combination of a PET Blow Molder, a Filler and a Capper combined into one block of equipement.

Integrated and compact preform decontamination, blow molding, filling and capping solution.

This machine is for PET filling and Aseptic PET filling lines.

Video

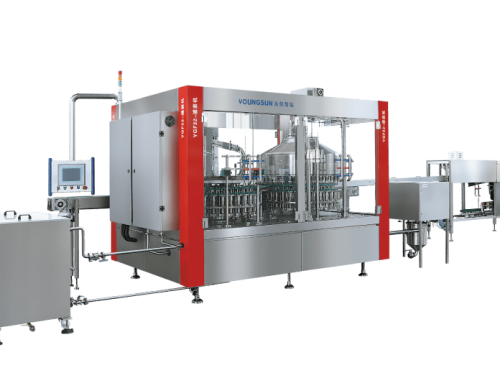

Blower + Filler + Capper Machine

Capacity: 36,000 BPH

Integrated combi-block Machine

watch the video >>