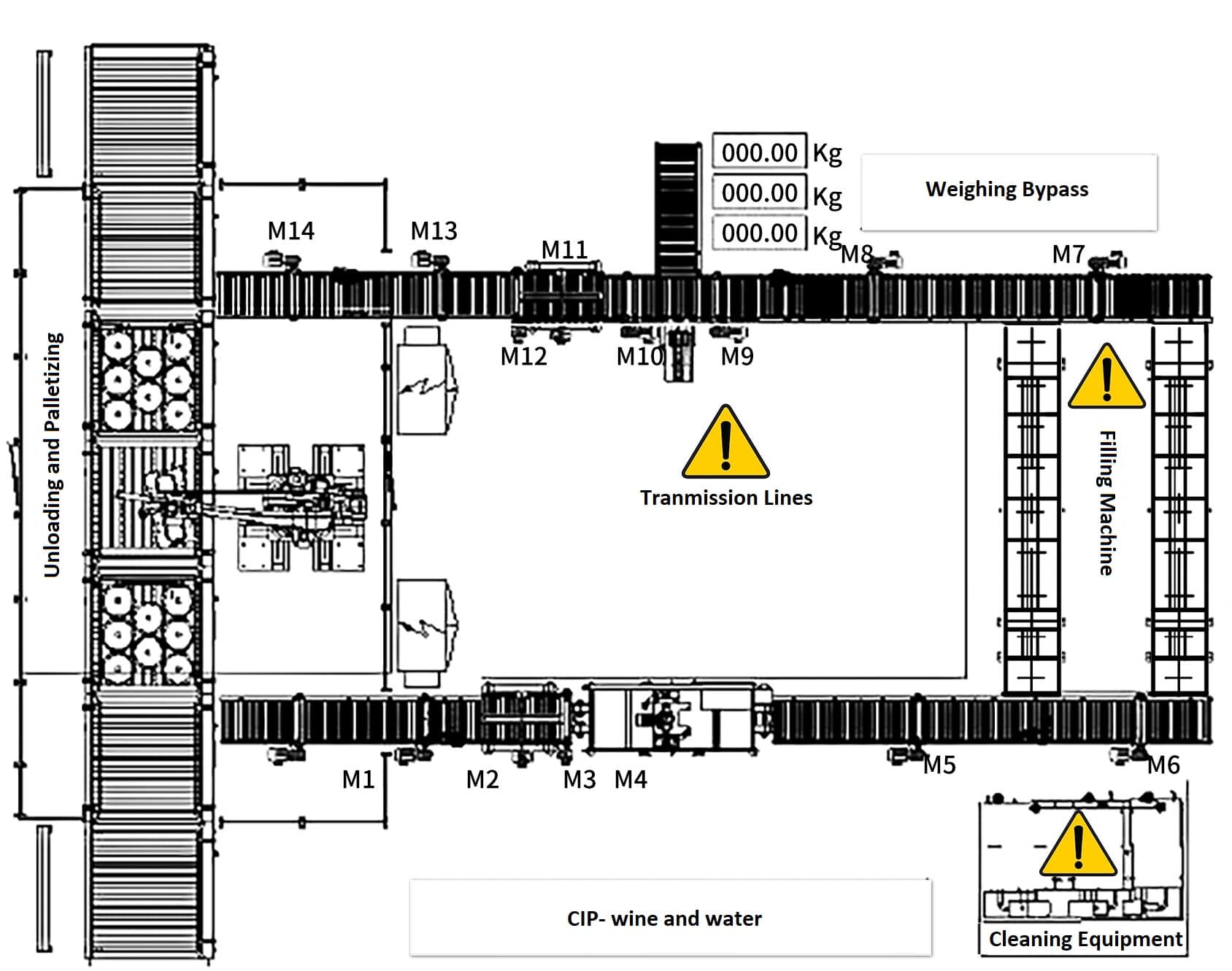

Fully Automatic Keg Filling line

Station 1

Residual liquid discharge, mixed water cleaning, air pressure purging with mixed water and alkaline water backwashing.

Station 2

Alkaline water immersion.

Station 3

Air pressure primary purging alkaline water, alkaline water cleaning, air pressure secondary purging alkaline water, mixed water cleaning, air pressure purging water.

Station 4

Hot water backwashing, air pressure purging hot water, hot water cleaning, air pressure secondary purging hot water.

Station 5

Steam purging and steam pressurization.

Station 6

Hot water cleaning, steam purging, steam sterilization.

Station 7

Steam sterilization the barrel mouth, CO2 primary purging, CO2 pressurization, beer filling, CO2 secondary purging at the barrel mouth, hot water cleaning the barrel mouth.

Videos

PDF Files coming soon.