CBM – –

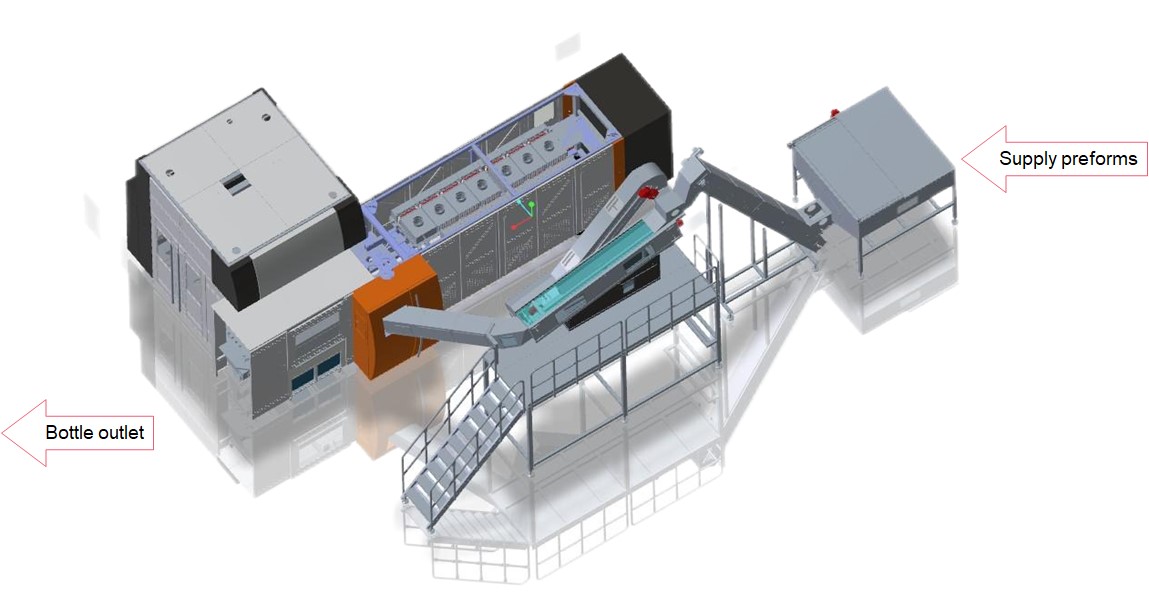

PET Bottle Rotary Blow Molding Machine

* Add notice about your Privacy Policy here

CBM – –

Rotary Stretch Blow Molding Machine for PET Bottle

* Add notice about your Privacy Policy here

High Efficiency PET bottle stretch blow molder

PET Blow Molding Machine Easy Operation And Great Flexibility

More Features:

- Three-blowing and two-recovery energy-saving technology: pressure difference cascade use, saving compressed air and energy about 40%.

- Mechanical sealing safeguard technology: The sealing track ensures that the sealing cylinder is raised quickly and absolutely, which is mainly used to ensure the safety of the high-speed blowing machine.

- Pre-blowing proportional valve control technology: The operation panel controls more precise process guarantees and energy-saving measures.

- Manipulator fork automatic clamping technology: the manipulator fork automatically opens and clamps the bottle mouth, to ensure that the bottle or preforms is more stable and not scratched.

- Heating and ventilation independent module: improve the modularization, general utilization and standardization, realize the module inlay technology, easy to install, maintain, and adjust the process.

- Servo stretching technology: it can quickly and accurately control the up and down moving speed and position of the stretching rod, realizing that stretch bottles of various height specifications by the same stretching rod, meet the stretching requirements of various preforms and solve the problem that some preforms are not easy to stretch.

- Heating lamp monitoring technology: real-time monitoring of heating lamps in each zone and layer of the heating oven, and interconnection with the operation panel, which can quickly and accurately check the use of heating lamps in each zone and layer of the heating oven.

- Cooling water circuit temperature inspection technology: real-time inspection of the cooling water inlet temperature, interconnection with the operation panel, data visualization, and accurate adjustment of the cooling water temperature according to the cooling effect of different bottle types.

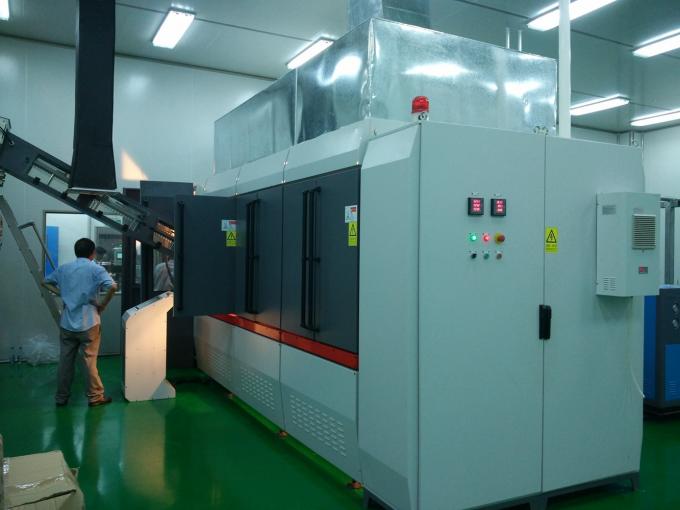

- High-speed, silent, low-consumption

You can visit Youngsun rotary PET blowing machine

Video

Blow molding Machine

Capacity: 36,000 cph

PET Bottle Blow molding machine

watch the video >>