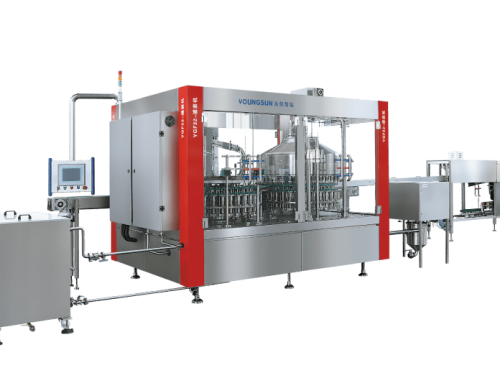

Can and Bottler Pasteurizer

Capacity:

Glass bottles: Up to 72.000 BPH

Cans: Up to 120.000 CPH

For Cans and Bottles

Brief Introduction of Tunnel Pasteurizer:

The fully automated pasteurizer is alternatively used for pasteurizing filled glass bottles or cans to ensure microbiological product safety, or as a warmer for cold-filled products to prevent surface condensation prior to labeling and packing. The machine is built in single or double deck execution depending on the required capacity.

Containers are evenly distributed for double deck machines by a special guide rail and divider system which ensures the equal container flow to both decks. Fallen containers at the infeed of the machine are reduced by 60% by special designed conveyors and extra thin dead plates. Alternative execution for lower investment costs in traditional design or for low operation costs with energy and water recovery and full PU control.

Technical advantages of can and Bottler pasteurizer:

· Guaranteed microbiological safety and flexibility.

· Traditional and energy efficient execution.

· Single or double deck execution.

· One click changeover for different SKU on HMI.

· Optimized and independent temperature control with a standby sensor in each zone.

· Crossed spraying nozzle position design to keep an even and stable spraying distribution.

· Central glass fragment discharge with a chain conveyor chain over the whole length of the machine including trolley.

· Doors on both sides of the machine which can be widely opened for bright working space and easy entry access.

· All motors in compact structure with small size and light weight.

· Horizontal installed pumps to avoid air lock and pressure loss.

· Operation platform around the machine for maintenance.

· Optional fully automated PU control.· Easy to clean and maintain.

· Optional system for lower bottle temperature at discharge with PHE or cooling tower for additional water saving.

SUSTAINABILITY:

· 80% reduction in water consumption. Additional water saving with water blow off and collection at the machine discharge.

· 40% reduction of steam consumption with insulated piping and housing. Independent hot water tank with a single PHE.

· Optimized pump module selection in class IE3 or above with power saving motors as option.

· Machine structure in stainless steel and spraying nozzles in clip on design for minimized maintenance.

* Add notice about your Privacy Policy here