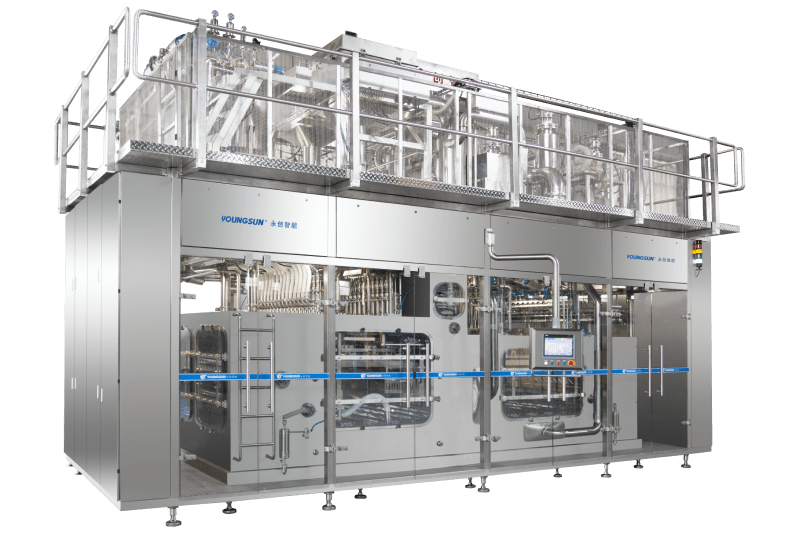

YSCSP10000 – YSCSP20000

Fully Automatic Ultra Clean Filling Capping Machine

Capacity:

Up to 20,000 bph

Applicable Filling Material (still and carbonated beverages): ESL Milk, Yogurt Drinks, Fresh Fruit Juice, Mineral Water, Ice-Tea, Flavored Water, and sensitive beverages.

Applicable Packaging Material: HDPE/PP/PS/PET Bottle

BRIEF INTRODUCTION:

Ultra Clean Filling Capping machine is designed for plastic bottles with hygienic standards.

It consists of bottle feeding, bottle picking, and transportation of vaporized hydrogen, peroxide sterilization and aseptic air drying, filling and capping, output systems, and transport.

| Main Technical Data: | ||

| Model | YSCSP-10000 | YSCSP-20000 |

| Production capacity: | 10,000 b/h | 20,000 b/h |

| Filling volume | 200ml-1000ml | |

| Applicable Filling material | still and carbonated beverages, yogurt drinks, milk, mineral water, Ice-tea, Juice, Flavored water | |

| Filling temperature | 4-40°C | |

| Filling error | ≤±0.5% | |

| production efficiency | ≥90% | |

| Qualification rate | ≥99.5% | |

| Single step specification | 12 bottle/step | 20 bottle/step |

| Total power | 34.5Kw | 38.5Kw |

| Running power | 40%-60% | |

| Power of motor | 24Kw | 28Kw |

| Other | 1Kw | 1Kw |

| Filling heads: | 12 | |

| Air pressure: | ≥0.6MPa | |

| Air consumption | ≥0.8m³/min | |

| Power supply | 3+N+PE 50Hz 380/220V±10%(3P 5 wires) | |

| Outer dimensions (appr.) | 8.3×3.7×3.5 m (L×W×H) | 8.3×4.2×3.5 m (L×W×H) |

| Machine weight (appr.) | 8.2 tons | 8.6tons |

| According to different characteristics of products, the capacity will be different. | ||

| Main Configuration: | |

| Servo motor: | Germany Siemens |

| Sensor: | Germany P+F |

| PLC: | Germany Siemens |

| Inverter: | France Schneider |

| Temperature: | Japan Omron |

Why do you need an Ultra Clean Filling machine or Ultra Clean system?

Suppose we want to achieve production without the use of preservatives and to minimize the number of micro-organisms in the space where bottles are sprayed and filled, in that case, it is essential to install the ULTRA-CLEAN system and Ultra Clean Filling capping machine.

principle of an ultra-clean system is replacing sterile air in the space where bottles are sprayed, filled, and capped.

* Add notice about your Privacy Policy here

Capacity:

Up to 20000 bph

Applicable Filling Material (Still Liquid): ESL Milk, Yogurt drinks, Fresh Fruit Juice, and delicate non-carbonated liquid.

Applicable Packaging Material: HDPE/PP/PS/PET Bottle

BRIEF INTRODUCTION:

Ultra Clean Filling Capping machine is designed for plastic bottles with hygienic standards.

It consists of bottle feeding, bottle picking, and transportation of vaporized hydrogen, peroxide sterilization and aseptic air drying, filling and capping, output systems, and transport.

| Main Technical Data: | ||

| Model | YSCSP-10000 | YSCSP-20000 |

| Production capacity: | 10,000 b/h | 20,000 b/h |

| Filling volume | 200g-700g | |

| Applicable Filling material | yogurt, milk, mineral water, beverage | |

| Filling temperature | 4-40°C | |

| Filling error | ≤±0.5% | |

| production efficiency | ≥90% | |

| Qualification rate | ≥99.5% | |

| Single step specification | 12 bottle/step | 20 bottle/step |

| Total power | 34.5Kw | 38.5Kw |

| Running power | 40%-60% | |

| Power of motor | 24Kw | 28Kw |

| Other | 1Kw | 1Kw |

| Filling heads: | 12 | |

| Air pressure: | ≥0.6MPa | |

| Air consumption | ≥0.8m³/min | |

| Power supply | 3+N+PE 50Hz 380/220V±10%(3P 5 wires) | |

| Outer dimensions (appr.) | 8.3×3.7×3.5 m (L×W×H) | 8.3×4.2×3.5 m (L×W×H) |

| Machine weight (appr.) | 8.2 tons | 8.6tons |

| According to different characteristics of products, the capacity will be different. | ||

| Main Configuration: | |

| Servo motor: | Germany Siemens |

| Sensor: | Germany P+F |

| PLC: | Germany Siemens |

| Inverter: | France Schneider |

| Temperature: | Japan Omron |

Why do you need an Ultra Clean Filling machine or Ultra Clean system?

Suppose we want to achieve production without the use of preservatives and to minimize the number of micro-organisms in the space where bottles are sprayed and filled, in that case, it is essential to install the ULTRA-CLEAN system and Ultra Clean Filling capping machine.

principle of an ultra-clean system is replacing sterile air in the space where bottles are sprayed, filled, and capped.